Beam

Gulf States Saw & Machine Company will also fulfill your Machine Parts order. You just need to complete a form. We will get back to you quickly!

.jpg)

This wire feeding device can connect wire feeder and reel together using wire feeding pipes. Wire reel supporter can be used to fix wire reel. Before welding, insert wire reel into supporter and then feed wire thrill through feeding tube.

The WS-72 website seamer station is equipped a Lincoln Power Wave DC welders, and Max-Sa control. The WS-72 employs special magnets that pull down the web plates to the copper back-up. The copper backing bar has a small, flux-like groove and is mounted into an aluminum watercooled sub-bar.

Gulf States Saw & Machine Company will also fulfill your Machine Parts order. You just need to complete a form. We will get back to you quickly!

.jpg)

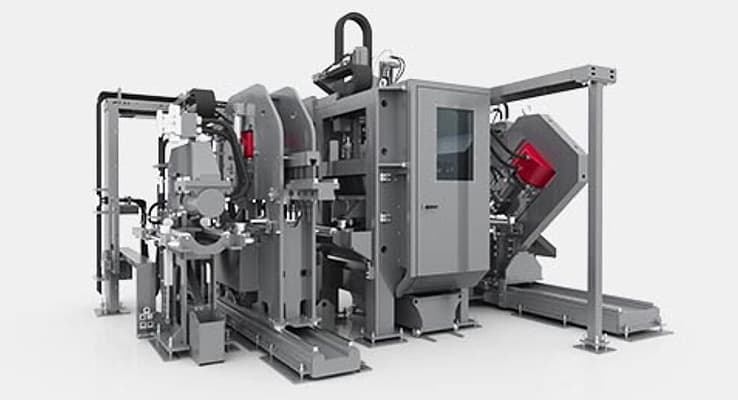

With the help of our Research & Development team, we can create the exact Beam Layout welding machine that you require. If you think it is possible, let us know and we will get back to your with our findings! Our engineers are more than happy to assist you! Get a quote for the equipment or products that you are looking for by contacting us today!

The clamps are released and the web is transferred to the tacking fixture. The welding equipment includes a flux hopper, travel carriage and controls. It also has a 1,000 Amp power supply. Full-color laser projectors will show all information needed to accurately tack-weld connections onto the beam or other connections.

H beams have different uses than I beams. Therefore, H beams can be used in different applications. In order to make an H beam welding system, there are several weld heads arranged next to each other.

H beams are not as widely used as I beams. So H beams are not necessarily better or more cost-effective than the I beams. In case you didn't know, an H beam welding device is composed of many weldheads stacked up next to each another.

A welded beam consists of three individual sections of steel – a web, a top flange and a bottom flange. These segments are merged together with deep fillet welds to create an incredibly robust building material.